News

Welding and Testing Parameters for Polypropylene (PP) Pipes with Wall Thicknesses up to 100 mm

At the Grevenbroich-Neurath lignite power plant, successful welding parameters for butt fusion welding of polypropylene with wall thicknesses of up to 100 mm were developed. These parameters ensure the safe and efficient use of components in flue gas cleaning systems.

PE 100-RC - A PE 100 with Extended Application Potential

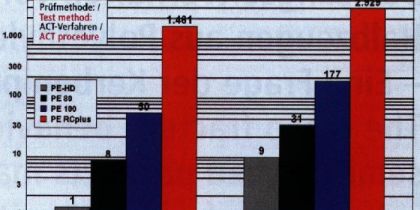

The development of PE 100 materials has established new standards in pipeline construction with the introduction of PE 100-RC, which is renowned for its exceptional resistance to slow crack growth, making it particularly suitable for alternative installation techniques.

Das Langzeitverhalten von Schweißverbindungen an Halbzeugen aus Polyethylen - Eine Frage der Kerbempfindlichkeit

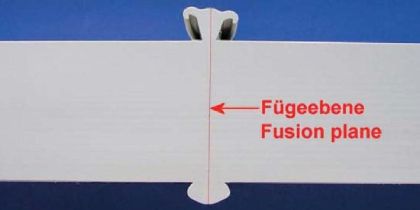

In butt fusion welding of polyethylene, notch-insensitive materials such as PE 100-RC offer significant long-term advantages, as fractures tend to occur in the base material rather than at the weld interface.

Economic Optimisation Potential of Pipes With a Crack Resistant Polyethylene and Protective Outer Layer during Heated Element Butt Welding

The ongoing optimization of polyethylene pipes, especially through the use of bimodal materials and protective coatings, enables the butt welding process to be accelerated without compromising the anticipated minimum lifespan of 100 years.

2nd Deutsches Symposium für die grabenlose Leitungserneuerung (German Symposium on Trenchless Pipeline Renewal), Universität Siegen

At the 2nd Deutschen Symposium für die grabenlose Leitungserneuerung (German Symposium on Trenchless Pipeline Renewal), Dr. J. Hessel addressed quality assurance for polyethylene pipes, focusing on ensuring safe and high-quality installations using trenchless methods.