News

Das Langzeitverhalten von Schweißverbindungen an Halbzeugen aus Polyethylen - Eine Frage der Kerbempfindlichkeit

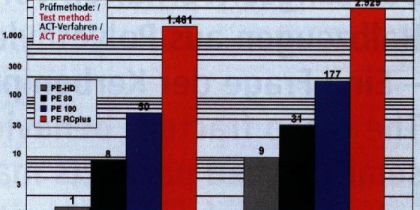

In butt fusion welding of polyethylene, notch-insensitive materials such as PE 100-RC offer significant long-term advantages, as fractures tend to occur in the base material rather than at the weld interface.

Economic Optimisation Potential of Pipes With a Crack Resistant Polyethylene and Protective Outer Layer during Heated Element Butt Welding

The ongoing optimization of polyethylene pipes, especially through the use of bimodal materials and protective coatings, enables the butt welding process to be accelerated without compromising the anticipated minimum lifespan of 100 years.

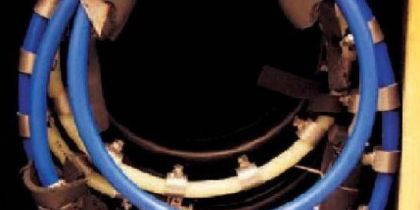

Qualitätssicherung für grabenlos verlegbare Rohre aus Polyethylen

In his presentation at the 2nd Deutschen Symposium für grabenlose Leitungserneuerung (German Symposium on Trenchless Pipeline Renewal), Dr. J. Hessel outlined six years of quality assurance for polyethylene pipes. He discussed the entire process, from raw material testing to advanced aging tests, which ensure consistently high quality in the pipes.

100 Jahre Nutzungsdauer von Rohren aus Polyethylen (Rückblick und Perspektive)

Dr. J. Hessel's study confirms the 100-year service life of polyethylene pipes for drinking water supply, emphasizing the reliability of modern extrapolation methods in predicting material properties.

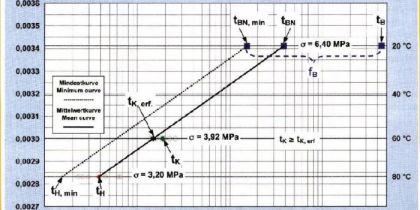

Checking of the required long-term tensile welding factor and the minimum time of welded joints made of polyethylene

The publication explains the testing procedure described in Supplement 3 of DVS Guideline 2203-4 for evaluating thermoplastic weld joints, which eliminates the need for unwelded reference samples and provides additional information on minimum service life.