News

High-density polyethylene (HDPE) lake pressure pipeline: Remaining service life after 47 years of operation in Lake Ossiach

In 1971, a high-density polyethylene (HDPE) pressure pipeline was installed in Lake Ossiach to efficiently discharge wastewater. Investigations and tests indicate that this pipeline can continue to operate for at least another 50 years, even though it has already reached its 50-year service life. Advances in HDPE materials and improved design standards could potentially extend its lifespan even further.

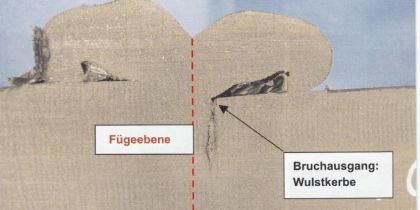

Long-term behavior of electrofusion joints in polyethylene pressure pipelines

Long-Term Behavior of Electrofusion Joints in PE Pressure Pipes: Circumferential cracks arise from stress concentrations. We recommend using an electrofusion joint factor of 0.4 in calculations, with PE 100-RC suitable for compensation. Defects often result from insufficient surface preparation, and experimental investigations reveal cracks across all manufacturers. It is essential to consider the electrofusion joint factor in PE pipe systems.

Trenchless close-fit installations in PE 100-RC quality

The Compact Pipe@ system for trenchless installation of gas, drinking water, and sewer pipes has been enhanced with PE 100-RC materials to improve crack resistance. Experiments demonstrate that the close-fit installed PE 100-RC pipe is durable under high loads and meets the requirements of PAS 1075.

TestPEP

The TestPEP project, funded by the European Community's Seventh Framework Programme, aims to develop and validate an automated non-destructive evaluation (NDE) method for testing welded joints in plastic pipes. Dipl.-Ing. J. Grieser presented on the development of flaw acceptance criteria for these welded joints.

Long-term behavior of welded joints in large-diameter polyethylene pipes

The development of large-diameter polyethylene pipes and their butt-welding technology requires new testing approaches. With adapted testing methods, creep rupture tests can now be performed on wall thicknesses up to 120 mm, using fewer samples and accounting for the typical fracture behavior of PE welds.