News

Sandbettlose Verlegung von PE-Rohren - Eine Frage der Rohrqualität

Over the past 30 years, the long-term strength behavior of polyethylene has improved due to advancements in raw material development. This raises the critical question of whether underground polyethylene pipes still require sand bedding. Current studies aim to determine the minimum quality level that allows for the elimination of sand bedding; some pipe qualities available on the market already meet this standard.

Long-term performance of infrared welded PVDF and PP Piping systems

Studies indicate that the long-term weld factor for PVDF-IR and HS welds can be set above 0.8. They also emphasize the importance of effective time-dependent behavior for the service life and safety of the weld connection. Infrared heating element butt welding has proven to be a technologically superior method, resulting in improved weld seam quality and has been successfully employed for about ten years for both PVDF and PP pipes.

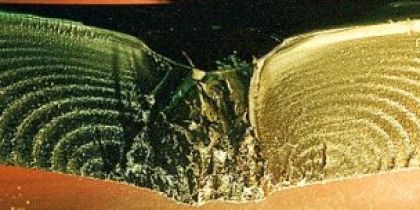

Minimum service-life of buried polyethylene pipes without sand-embedding

In the past, it has been shown that the service life of buried pipes is reduced due to stress concentrations caused by external point loads. The longevity of the pipes is closely linked to the material's resistance to slow crack propagation. Polyethylene resins are continuously developed to enhance resistance to crack growth. These improvements are reflected in the time-to-failure curves of various standards from 1976 to 2000. The question arises whether the current resins' resistance to slow crack growth has reached a stage where failure of pressure pipes under additional external point loads during their service life is unlikely.