Long-term behavior of electrofusion joints in polyethylene pressure pipelines

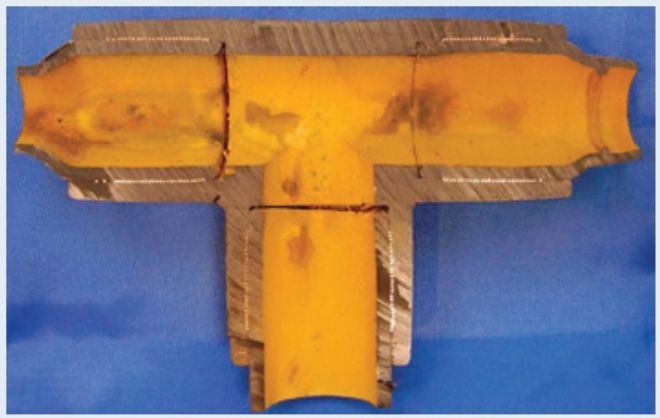

Long-Term Behavior of Electrofusion Joints in PE Pressure Pipes: Circumferential cracks arise from stress concentrations. We recommend using an electrofusion joint factor of 0.4 in calculations, with PE 100-RC suitable for compensation. Defects often result from insufficient surface preparation, and experimental investigations reveal cracks across all manufacturers. It is essential to consider the electrofusion joint factor in PE pipe systems.

In calculating polyethylene piping systems with both butt fusion and electrofusion joints, it is essential to consider "electrofusion joint factors" (similar to the long-term welding factors for butt fusion joints). The electrofusion joint factor is set at 0.4. Compensation is achievable in PE 100 piping systems when using electrofusion fittings made from PE 100-RC.

3R international - Issue 07/08, 2015, pages 74-78