Notched Pipe Test (NPT) on pipes OD 315 x 18.7 (SDR17) following DIN EN ISO 13479

The Notched Pipe Test performed on pipes with an outside diameter (OD) of 315 mm is uncommon but feasible. Owing to the size of the test specimens, the preparation of standard-compliant notches, the pressure-tight sealing of the specimens and the immersion in the test liquid represent significant technical challenges.

The Notched Pipe Test performed on pipes with an outside diameter (OD) of 315 mm is uncommon but feasible. Owing to the size of the test specimens, the preparation of standard-compliant notches, the pressure-tight sealing of the specimens and the immersion in the test liquid represent significant technical challenges.

Figure 1 illustrates the test specimens in comparison with reference persons. The dimensional difference between NPT specimens with OD 315 mm and OD 110 mm is shown in Figure 2.

The Notched Pipe Test (NPT) is a test method for the determination of the resistance to slow crack growth of pipes manufactured from PE-HD or PE 100-RC materials.

During the test, a pipe provided with an external notch is subjected to a specified internal pressure. The tensile stresses generated in the pipe wall by the applied internal pressure result in the initiation of stress cracks at the notch root. Crack propagation proceeds continuously through the pipe wall. Acceleration of the test is achieved by immersion of the test specimen in a surfactant solution with stress crack–inducing properties at a temperature of 80 °C. The time to failure of the pipe is recorded and used as an indicator of the resistance to slow crack growth (SCG). The test method is specified in the international standard DIN EN ISO 13479.

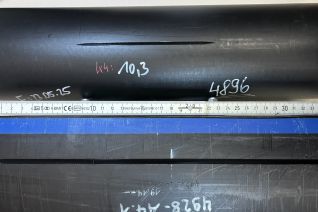

As the NPT is intended for the assessment of the raw material, pipes with the dimension OD 110 × 10 mm (SDR 11) are used in the majority of cases. Although the application of the NPT to pipes with OD 315 mm is specified in DIN EN ISO 13479, such testing is rarely performed in practice due to the associated technical complexity. The difference in notch size between a pipe with an outside diameter of 315 mm and a pipe with an outside diameter of 110 mm is clearly visible in Figure 3. Figure 4 shows the fracture surfaces at the opened notches of the pipes with outside diameters of 315 mm and 110 mm arranged side by side.

Owing to the high capacity of our test rigs, the pipes could be tested simultaneously in the NPT, thereby reducing the overall test duration to a minimum. In combination with our extensive expertise, this enabled parallel testing of pipes with a diameter of OD 315 under accelerated test conditions in accordance with PAS 1075 (NPT+). As a result, reliable and meaningful test results were provided to the customer within a short time frame and to their full satisfaction.