Plastics Pipes Conference XIV, Budapest, Ungarn

The Plastics Pipes Conference XIV was held in Budapest in September 2008, where Dr. J. Hessel introduced new approaches for testing PE and PA 12 pipes, along with advancements in the thermal aging process for PE 100 pipes. These methods enable more cost-effective and efficient testing to ensure pipe performance and safety.

The Plastics Pipes Conference XIV was held in September 2008 in Budapest, Hungary, where Dr. J. Hessel delivered several notable presentations on key topics:

- Resistance to internal pressure of large diameter PE-pipes - A new approach using a cost-cutting test method

In this presentation, a new approach to determining the creep rupture strength of large diameter PE pipes was discussed. Given the increasing use of such pipes in pressure systems, it was important to find a reliable method for determining their long-term creep rupture strength. The hydrostatic strength requirements at 80°C for PE pipes (e.g., according to EN 12201-2) were determined by internal pressure tests with pipes of different outer diameters. This innovative approach enabled efficient and cost-effective testing to ensure the safety and performance of PE pipes. - Buried PA 12 pipes for the transport of gas & water; No sand embedding necessary?

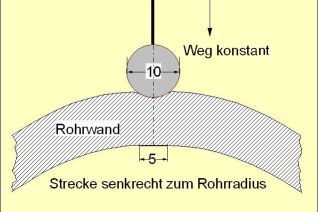

This presentation discussed the use of PA 12 pipes for the transport of gas and water. Interestingly, the necessity of sand embedding was questioned. The investigation focused on the resistance to internal pressure of PA 12 pipes, particularly concerning external point loads. It was examined whether the creep rupture strength of current PA 12 resins has reached a state where failure of pressure pipes with additional external point loads during their lifetime is not expected. This presentation provided valuable insights for the practice and future development of pipeline systems. - Thermal ageing of PE 100 pipes for accelerated lifetime prediction under service conditions

(H. Vogt, H.-F. Enderle, U. Schulte - Basell Polyolefine GmbH und Dr. J. Hessel - Hessel Ingenieurtechnik GmbH)

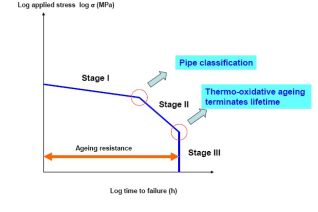

This presentation examined the thermal ageing of PE 100 pipes to enable accelerated lifetime prediction under real operating conditions. It is generally accepted that the maximum lifetime of pipes made from bimodal HDPE types has reached a stage where the lifetime of the material is only limited by its resistance to thermal ageing. The time to the onset of this degradation mainly depends on the stabilization package, the applied temperature, the oxygen concentration, and the type and flow rate of the medium. To simulate the long-term stability of HDPE pipes under real conditions, thermal ageing under internal pressure with circulating or standing water at elevated temperatures was conducted until brittle failures occurred. The progress in ageing was examined on samples from the installed pipes, and changes in the molecular structure and antioxidant concentration were determined. Activation energies were calculated and compared with other parameters such as the loss of oxidation induction time. This innovative approach enabled efficient and cost-effective testing to ensure the safety and performance of PE 100 pipes.

Gallery

Downloads

Resistance of large diameter PE pipes to internal pressure - A new approach using a cost-cutting test method (EN)pdf | 975,91 KB

Resistance of large diameter PE pipes to internal pressure - A new approach using a cost-cutting test method (EN)pdf | 975,91 KB Buried PA 12 pipes for then transport of gas & water; No sand embedding necessary? (EN)pdf | 123,86 KB

Buried PA 12 pipes for then transport of gas & water; No sand embedding necessary? (EN)pdf | 123,86 KB Thermal ageing of PE 100 pipes for accelerated lifetime prediction under service conditions (EN)pdf | 575,86 KB

Thermal ageing of PE 100 pipes for accelerated lifetime prediction under service conditions (EN)pdf | 575,86 KB