Minimum service-life of buried polyethylene pipes without sand-embedding

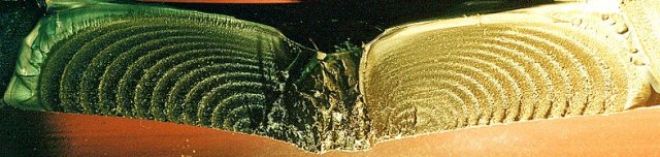

In the past, it has been shown that the service life of buried pipes is reduced due to stress concentrations caused by external point loads. The longevity of the pipes is closely linked to the material's resistance to slow crack propagation. Polyethylene resins are continuously developed to enhance resistance to crack growth. These improvements are reflected in the time-to-failure curves of various standards from 1976 to 2000. The question arises whether the current resins' resistance to slow crack growth has reached a stage where failure of pressure pipes under additional external point loads during their service life is unlikely.

In the past, it has been shown that the service life of buried pipes is reduced due to stress concentrations caused by external point loads. The longevity of the pipes is closely linked to the material's resistance to slow crack propagation. Polyethylene resins are continuously being developed to increase resistance to crack growth. This increase is evident in the time-to-failure curves of various standards from 1976 to 2000 (e.g., DIN 8075). However, many current resins show time-to-failure values that significantly exceed minimum requirements. This raises the question of whether the resistance of current resins to slow crack propagation has reached a developmental stage where failure of pressure pipes under additional external point loads during their service life is not to be expected.

3R international 40 (2001) Special Plastic Pipes, Pages 4-12