Welding and Testing Parameters for Polypropylene (PP) Pipes with Wall Thicknesses up to 100 mm

At the Grevenbroich-Neurath lignite power plant, successful welding parameters for butt fusion welding of polypropylene with wall thicknesses of up to 100 mm were developed. These parameters ensure the safe and efficient use of components in flue gas cleaning systems.

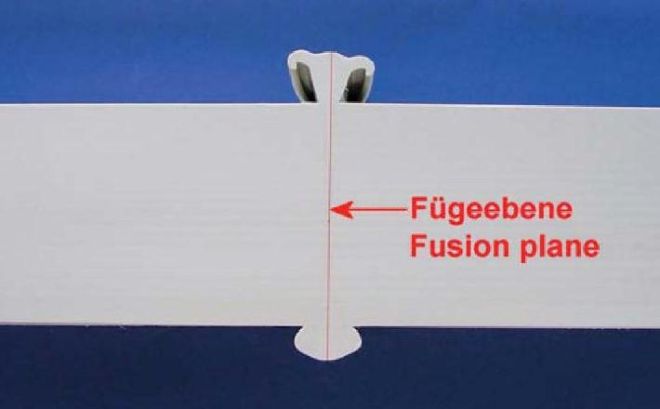

In the flue gas cleaning system at the Grevenbroich-Neurath lignite power plant, components made of polypropylene are employed. The participating plastic companies were tasked with developing welding parameters for butt fusion welding of PP with wall thicknesses of up to 100 mm within a six-month timeframe. Following DVS guidelines, specific welding parameters and testing requirements were established. Test welds with wall thicknesses of 25, 50, 75, and 100 mm were evaluated using rigorous testing procedures. Preliminary results from the technological bending tests confirm that the selected welding parameters are effective for joining polypropylene components with wall thicknesses up to 100 mm using the butt fusion welding process, achieving the necessary quality standards.

JOINING PLASTICS - Joining of Plastics Issue 1/2008, pages 46-49