Cost- and time-saving method for generating creep curves for plastic pipes.

The strength-related design of plastic structures is typically conducted using creep rupture curves. This article describes a testing method for generating reliable creep curves for thermoplastic pipes, aimed at reducing uncertainties in calculating the minimum stress over a 50-year lifespan.

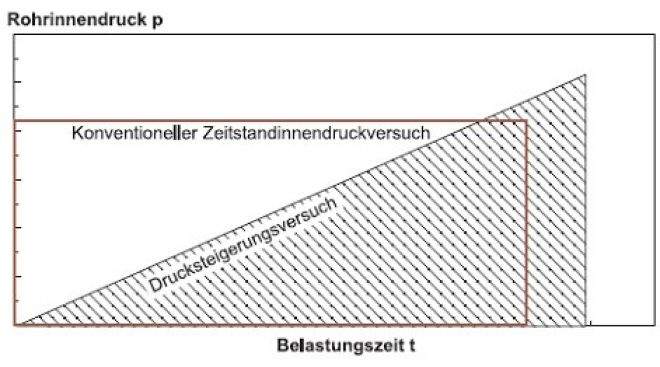

Generating creep rupture curves for pipes used in the design of multi-axially loaded components typically requires significant experimental effort and complex regression analysis, even when dealing with simple linear creep curves. The "linear pressure increase" method described here simplifies the calculation of creep rupture curves for pipes, reducing both effort and time. This work outlines the application possibilities and theoretical background of the model.

3R international (48) Issue 11/2009, pages 2-5